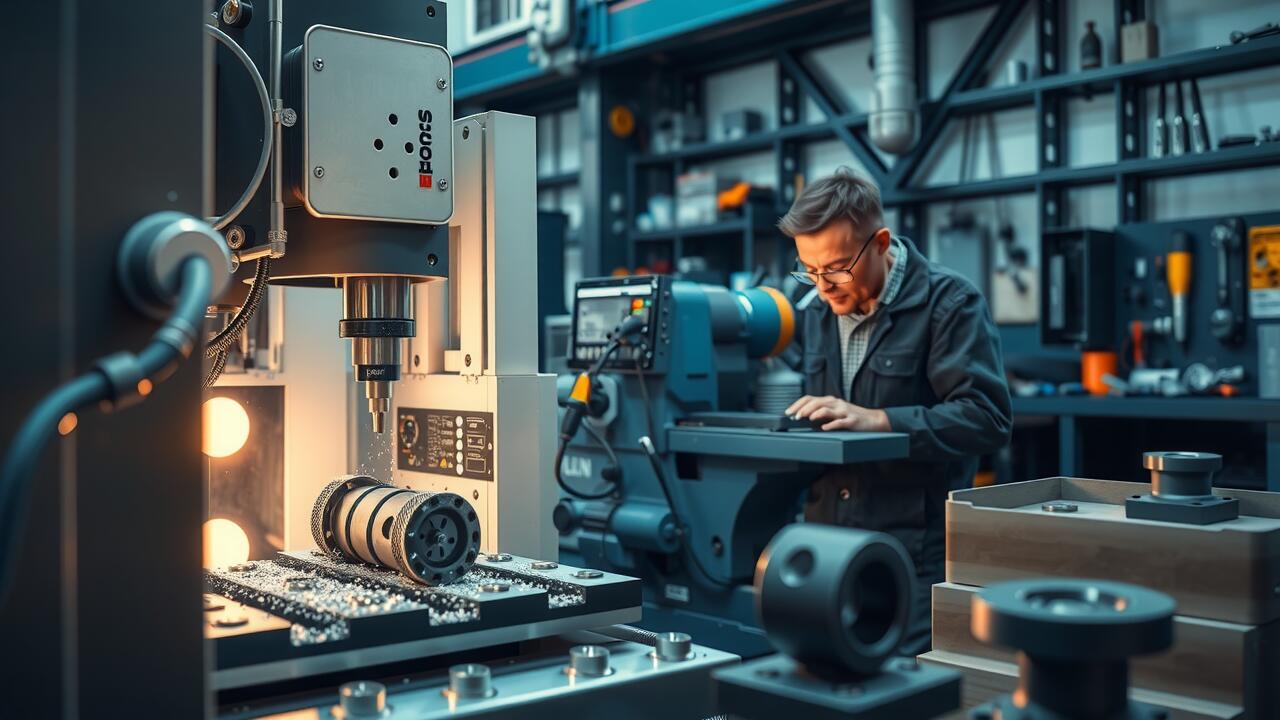

An Expert’s Analysis of CNC Machining Versus Manual Milling in Custom Part Production

Table Of Contents

Flexibility in Design

Custom fabrication has opened the door for manufacturers to create highly specialized parts that meet evolving client demands. With CNC machining, the flexibility in design allows engineers to tweak specifications on the fly, accommodating changes in customer requests without significant downtime. For instance, a company producing aerospace components might receive an urgent request for modifications in dimensions or materials. CNC technology enables quick adjustments, which is crucial in competitive markets where speed and precision matter.

Manual milling, while still valuable, tends to impose more constraints on design modifications. Operators often require more time to adjust setups or learn new specifications, limiting the ability to rapidly adapt to shifting project requirements. This difference becomes apparent in environments focused on custom fabrication services where time is of the essence. A study indicates that projects utilizing CNC processes can reduce lead times by up to 30%, demonstrating how design flexibility directly influences production efficiency and customer satisfaction.

Why is Design Flexibility Important for Manufacturers? (Adapting to Client Needs)

Design flexibility serves as a cornerstone for manufacturers aiming to thrive in highly competitive markets. The ability to adapt designs on-the-fly can significantly enhance responsiveness to client needs. For instance, a manufacturer specializing in custom fabrication might get last-minute requests for a specific part variation. By implementing CNC machining, they can easily reprogram the machinery to accommodate rapid changes without delaying production schedules. This level of adaptability not only meets customer expectations but also attracts a broader clientele looking for tailored solutions.

Moreover, having the capability to pivot designs quickly directly impacts a company’s bottom line. A facility that utilizes CNC technology can typically reduce lead times by 30 to 50 percent compared to traditional manual milling processes. This efficiency allows businesses to take on more orders and meet varying market demands effectively. Emphasizing quick turnaround times in custom fabrication services not only improves client satisfaction but also enhances the company's reputation for reliability. In an ever-evolving industry landscape, staying agile is crucial for long-term success.

Workforce Skill Requirements

The skill sets required for CNC machining and manual milling differ significantly, reflecting the technological demands of each method. CNC machining often requires workers to be well-versed in programming languages and software applications. For example, technicians might need to understand G-code and CAD/CAM systems to ensure the machinery operates efficiently. In contrast, manual milling relies on tactile skills and a deep understanding of mechanical processes. Operators must demonstrate proficiency in interpreting blueprints while applying manual techniques to achieve precise cuts and finishes.

Training for these roles also varies considerably. Employers offering custom fabrication services usually invest in specialized training programs for CNC operators to keep up with advancements in automation and software. Companies often seek workers with formal education, such as certificates or degrees in machining technology. For manual milling positions, apprenticeship programs and hands-on experience are common routes, emphasizing practical skills and problem-solving abilities. Skills in both domains are critical, especially as the industry evolves toward integrating more sophisticated technologies into custom fabrication processes.

How Do Skill Sets Differ Between CNC Machining and Manual Milling? (Training Essentials)

CNC machining and manual milling require distinct skill sets that reflect the underlying technology and processes. CNC machinists need a strong understanding of computer programming and software, as well as familiarity with various CAD/CAM systems. They often undergo specific training programs that cover everything from computer-aided design to toolpath generation. This allows them to produce custom fabrication pieces with precision. For example, a CNC machinist might use software like Mastercam to streamline production workflows, significantly reducing lead times. On the other hand, manual milling operators depend heavily on traditional machining techniques. They must trust their hands and eye coordination along with a sound grasp of material properties to execute complex cuts manually.

Training for manual milling tends to be more hands-on, with apprenticeships or on-the-job experiences being crucial for competency. These skills can take longer to master, sometimes exceeding several years for a machinist to achieve full proficiency. While both skill sets are valuable, CNC machining often grants organizations greater scalability, allowing for rapid design iterations and efficient production of custom fabrication services. Manual milling, although slower, often allows for intricate details that might be challenging to achieve using automated processes. Balancing these differing skills in a production environment can enhance overall productivity while meeting diverse customer needs.

Maintenance and Longevity

Regular maintenance is crucial for prolonging the lifespan of CNC machines and manual mills. Manufacturers should establish routine checks that include inspecting spindle bearings, lubrication levels, and accuracy of cutting tools. For instance, reports from manufacturers indicate that consistent preventative maintenance can reduce the frequency of major repairs by up to 25%. This not only saves time but also money by minimizing equipment downtime. Neglecting these practices can lead to a decline in precision and efficiency, significantly impacting the quality of custom fabrication.

On the other hand, the longevity of manual milling machines largely depends on the operator's skills and their ability to perform repairs and adjustments. While CNC equipment may require specialized training for technicians, manual mills allow for easier troubleshooting and on-the-fly modifications. Custom fabrication services can benefit from a workforce skilled in both types of machining, enabling flexibility in responding to intricate demands. By integrating best practices such as proper cleaning and regular tool calibrations, businesses can ensure their equipment remains reliable and effective for years to come.

What Maintenance Practices Extend Equipment Lifespan? (Routine Checks and Repairs)

Regular maintenance can significantly increase the longevity of CNC and manual milling equipment, minimizing unexpected downtime. Performing routine checks on key components such as spindle bearings and tool holders will help catch any wear and tear early on. For instance, checking the coolant levels and filters can prevent overheating, which contributes to system failures. An equipment maintenance schedule that includes daily inspections and monthly detailed servicing often saves manufacturers from costly repairs or even total machinery replacements down the line.

Implementing standardized practices according to the manufacturer's guidelines should be a priority, especially for those relying on custom fabrication services. Following these protocols can ensure that operators are aware of any necessary adjustments and repairs. For example, cleaning the machine regularly can prevent chips and debris buildup, which can impair precision over time. Keeping a maintenance log is also beneficial; tracking repairs and services provides valuable insight into equipment performance trends. This approach not only elevates productivity but also enhances the quality of finished products.

Technology Integration

The rise of technology in manufacturing has transformed how custom fabrication services operate, particularly in CNC machining. Automated systems streamline production processes, increasing efficiency. For instance, manufacturers can reduce cycle times by up to 50% through the integration of advanced software. This allows for rapid adjustments to part designs based on client feedback without compromising quality. Real-time monitoring tools further enhance operational performance by predicting machine maintenance needs before breakdowns occur.

Moreover, adopting tech-driven solutions fosters dedicated design teams to focus on optimizing product design and customer satisfaction. For example, design simulation software can predict how a part will behave in real-world conditions, leading to better material selection and maximizing resources. Incorporating these technologies not only makes processes smoother but also opens avenues for more intricate custom fabrication projects, helping manufacturers maintain a competitive edge. Companies that effectively leverage data analytics often see a 20% increase in productivity, demonstrating the tangible benefits of embracing technology in custom part production.

How Can Technology Enhance Custom Part Production? (Software and Machinery Synergy)

Integrating advanced software with CNC machinery streamlines the custom fabrication process significantly. Programs like CAD (Computer-Aided Design) allow designers to create intricate designs that can be directly interpreted by CNC machines. For example, a company specializing in aerospace components leveraged such technology to reduce their production time by 30%, all while maintaining precision within 0.001 inches. This synergy between software and machinery enables rapid prototyping and efficiently tackles complex designs, which traditional manual milling might struggle to execute.

On the operational side, embracing technology in custom fabrication not only speeds up production but also enhances quality control. With real-time data collection and analysis, manufacturers can monitor processes continuously, catching deviations early. A leading automotive parts manufacturer increased their yield rate by 15% after implementing smart monitoring systems that provide instant feedback. Industry standards often stress the importance of precision, and tech integration ensures that manufacturers remain compliant. Regular software updates and machine calibrations become crucial practices as companies seek to maintain competitive advantage.

- Streamlines the design-to-production workflow, reducing lead times.

- Increases accuracy and minimizes human error during fabrication.

- Allows for quick adjustments and modifications to designs on the fly.

- Enhances collaboration between design and manufacturing teams through shared software platforms.

- Enables the production of customized parts tailored to specific customer needs.

- Facilitates better inventory management with predictive analytics and trend monitoring.

- Supports sustainable practices by optimizing material usage and reducing waste.

Real-World Applications

When it comes to real-world applications, CNC machining shines in the aerospace and automotive industries. For instance, companies requiring high-precision components rely on CNC for custom fabrication of engine parts. These components need to meet strict tolerances, often within 0.005 inches, to ensure functionality and safety. A notable case is Boeing, which leverages CNC machining for critical aircraft components, demonstrating how precision impacts performance and operational efficiency.

On the other hand, manual milling still finds its niche in small-scale custom fabrication services, particularly for one-off prototypes or specific artistic pieces. Artists and craftsmen often prefer manual milling for its tactile feedback and adaptability. The ability to make quick adjustments on the fly can’t be understated; this flexibility allows creators to breathe life into unique designs that might otherwise be constrained by rigid CNC programming. These divergent applications highlight how both methods cater to diverse needs in the manufacturing landscape.

FAQS

What are the main differences between CNC machining and manual milling?

CNC machining uses computer-controlled machinery for precision and efficiency, while manual milling relies on human skill to operate the machine. This often makes CNC machining better for complex designs and high-volume production.

Why is design flexibility important in custom part production?

Design flexibility allows manufacturers to adapt quickly to client needs and market changes, ensuring they can create parts that meet specific requirements without extensive retooling or delays.

What skills are needed for CNC machining compared to manual milling?

CNC machining typically requires knowledge of programming and computer software, while manual milling focuses more on hands-on skills and understanding of machine operation. Both require a good understanding of materials and machining principles.

How can I extend the lifespan of my CNC machines or manual mills?

Regular maintenance practices, such as routine checks, cleaning, lubrication, and timely repairs, can significantly extend the lifespan of both CNC machines and manual mills.

What role does technology play in custom part production?

Technology enhances custom part production by integrating advanced software solutions with machinery, improving efficiency, precision, and the ability to produce complex designs with ease.