Trends Shaping the Future of Sheet Metal Fabrication in 2024

Table Of Contents

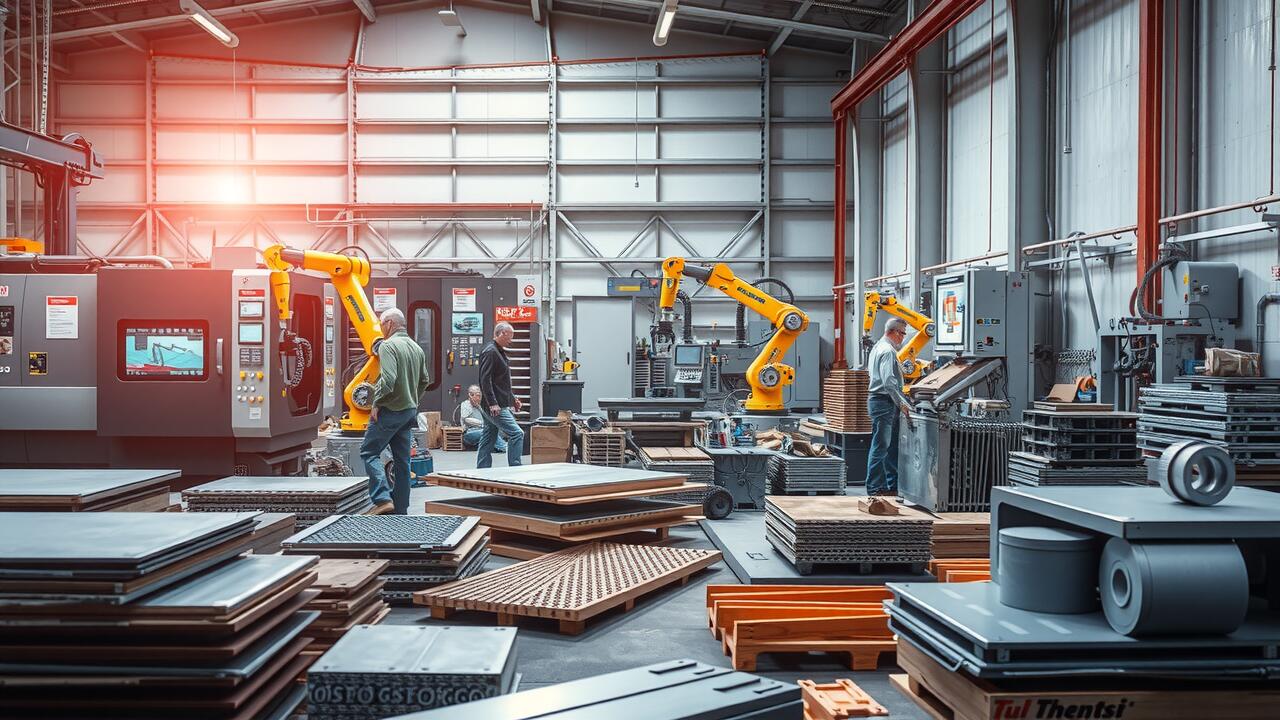

Integration of Robotics in Fabrication Processes

The adoption of robotic systems in fabrication processes offers a significant edge to companies specializing in custom fabrication. For instance, integrating collaborative robots, or cobots, can enhance workflows by assisting human workers, particularly in repetitive tasks like welding or material handling. These machines are designed to work safely alongside people, which allows for a smoother transition in tasks and reduces downtime. This collaborative approach often leads to enhanced precision and consistency in the final product, essential for businesses aiming to meet stringent industry standards.

A study revealed that companies using robotics in their operations witnessed productivity increases of over 30%. One notable example is a mid-sized fabricator that integrated a robotic arm for laser cutting. This investment cut their labor costs by 20% while improving cutting accuracy. By utilizing robotic assistance, fabricators can optimize their custom fabrication services, streamline operations, and ultimately achieve higher output rates without sacrificing quality. Embracing this technology not only addresses labor shortages but also positions businesses to scale effectively amidst increasing demand.

What Are the Benefits of Collaborative Robots in Workshops?

Collaborative robots, often known as cobots, bring a fresh perspective to custom fabrication workshops. These machines enhance productivity by taking over repetitive tasks, enabling skilled workers to focus on more complex and creative projects. For instance, a recent case study showed a metal fabrication shop that integrated cobots into their assembly line increased output by 35% while improving overall product quality. This shift not only streamlines operations but also effectively reduces the risk of workplace injuries, which leads to a safer environment for staff.

One significant advantage of implementing cobots is their ability to work alongside human operators without requiring extensive safety cages. This seamless collaboration allows operators to collaborate closely with these robots, making real-time adjustments as needed. This is especially meaningful in custom fabrication services, where precision is critical. Data from industry reports indicates that shops using cobots can achieve up to a 50% reduction in turnaround time for custom projects. This enhanced efficiency ultimately translates into increased customer satisfaction and competitive advantage in a fast-paced market.

Cost Management Strategies for Fabricators

Navigating the financial landscape of sheet metal fabrication requires keen attention to cost management strategies. Many fabricators are turning to lean manufacturing to streamline processes and minimize waste. For instance, implementing just-in-time (JIT) inventory reduces excess materials lying around, saving both space and money. Custom fabrication services that prioritize efficiency over bulk orders can also help meet market demand without incurring unnecessary expenses.

Utilizing advanced software for project management has become another smart tactic. Digital tools allow for real-time tracking of costs and resource allocation, which helps identify areas where expenses can be trimmed. For example, companies that leverage software analytics often see a 15-20% reduction in operational costs within a year, simply by making data-driven decisions. Another actionable strategy involves negotiating better deals with suppliers or consolidating orders to benefit from volume pricing, ensuring high-quality materials without breaking the bank.

5 Key Strategies for Reducing Overhead Without Sacrificing Quality

Efficient training programs play a crucial role in reducing overhead costs while maintaining top-notch quality. Investing in worker development helps build skills that align closely with specific machinery and processes used in custom fabrication. Companies that adopt this approach often see productivity spikes, with some reporting a 20% increase in output after implementing structured training courses. For instance, manufacturers that utilize simulations and practical workshops typically optimize operator skillsets, leading to faster turnaround times and fewer errors in fabrication tasks.

Another impactful strategy involves streamlining workflows through lean practices, such as value stream mapping. Pinpointing waste in processes allows fabricators to identify unnecessary steps that don’t contribute to quality or output. For example, a fabrication shop that reorganizes its layout can reduce material handling time by as much as 30%. Pairing this with just-in-time inventory can minimize storage costs and reduce the risk of overstocking raw materials, a common challenge in industries reliant on custom fabrication services. By focusing on these techniques, businesses can effectively cut costs without compromising quality.

The Impact of Supply Chain Dynamics

Supply chain dynamics can significantly affect custom fabrication processes, especially when it comes to sourcing materials and components. For instance, a recent study showed that 70% of manufacturers experienced delays due to material shortages in 2023. Companies relying on a steady influx of raw materials saw their production schedules thrown off balance, which often leads to missed deadlines and unhappy clients. Fabricators looking to stay ahead must adapt by diversifying their supplier networks and considering local sourcing options to minimize disruptions.

Preparing for material shortages requires strategic foresight and robust planning. Implementing inventory management software can help track stock levels and anticipate needs based on historical data and market trends. Moreover, developing strong relationships with multiple suppliers fosters reliability; for example, a fabricator that sources aluminum from three distinct vendors ensures they have alternatives in case one supply line falters. By proactively addressing these supply chain challenges, companies can continue to offer custom fabrication services with minimal delays and maintain their competitive edge in the market.

How Can Manufacturers Prepare for Material Shortages?

Manufacturers are turning to advanced forecasting techniques to navigate material shortages adeptly. By leveraging tools like demand planning software, companies can analyze trends and historical data to predict material needs more accurately. For instance, a fabricator focusing on custom fabrication found that integrating predictive analysis reduced material waste by 30%. This not only minimizes costs but also ensures that the supply chain remains resilient even in unpredictable markets.

Collaborative relationships with suppliers are becoming necessary in preparation for potential shortages. Establishing long-term agreements can enhance reliability, allowing fabricators to lock in pricing and maintain steady access to essential materials. For example, a business that specializes in custom fabrication services successfully negotiated multi-year contracts with key suppliers, which helped them navigate fluctuations during global disruptions. As a result, they maintained production schedules and customer satisfaction, illustrating the importance of strategic partnerships in today's supply chain landscape.

- Develop a diversified supplier base to reduce dependency on single sources.

- Invest in inventory management systems to track stock levels and reduce overordering.

- Regularly review and update suppliers’ performance and reliability.

- Implement risk assessment strategies to identify potential bottlenecks in the supply chain.

- Foster open communication with suppliers to stay informed about market conditions and potential issues.

- Train staff on adaptive strategies for quick decision-making in response to shortages.

- Create contingency plans outlining steps to take in case of material shortages.

Embracing Digital Twin Technology

Digital twin technology is transforming how workshops approach custom fabrication. By creating a virtual replica of physical objects, fabricators can simulate and optimize manufacturing processes before any actual work begins. For instance, a leading automotive parts manufacturer used digital twins to reduce design-to-production time by 30%. This simulation approach allowed them to identify potential issues early in the design cycle, minimizing costly changes later in production.

Implementing this technology can help fabricators enhance their workflow efficiency significantly. Using data from real-time sensors, companies can continuously monitor equipment and process performance. A study found that businesses using digital twins improved their predictive maintenance efforts, resulting in a 20% reduction in downtime. For those offering custom fabrication services, adopting digital twin technology can lead to considerable competitive advantages, as it enables precise adjustments tailored to client specifications without sacrificing quality.

Why Should Fabricators Consider Simulation for Process Optimization?

Simulation technology offers sheet metal fabricators a fantastic way to streamline processes and enhance efficiency. For instance, employing virtual models allows teams to predict how materials will behave during fabrication. This proactive approach can significantly reduce material waste by identifying potential issues before hitting the shop floor. When companies utilize simulation, they can forecast the outcome of various fabrication techniques, making adjustments that optimize production rates while maintaining quality.

The advantages extend to logistics and scheduling as well. By simulating the entire production process, from cutting to assembly, fabricators can better manage their time and resources. This means fewer unexpected delays and a smoother workflow overall. For businesses offering custom fabrication services, these efficiency gains translate into faster turnaround times for clients. Studies show that fabricators embracing simulation see up to a 30% reduction in lead times, enabling them to meet stringent delivery deadlines while minimizing costs.

The Shift Towards Lean Manufacturing Practices

Businesses are increasingly adopting lean manufacturing practices to streamline operations and enhance efficiency. Custom fabrication services often implement techniques like value stream mapping to identify wasteful processes. For instance, a sheet metal fabrication shop might analyze its workflow to reduce lead times by 30%, improving order fulfillment rates and customer satisfaction. By minimizing unnecessary steps and optimizing resource allocation, fabricators can reduce costs while boosting productivity.

Additionally, companies are embracing Just-In-Time (JIT) inventory management as part of their lean strategies. This approach allows for precise material delivery aligned with production schedules, significantly decreasing storage costs and minimizing waste. A case study from a Midwest fabrication facility showed that implementing JIT principles resulted in a 20% reduction in inventory costs and improved cash flow. By focusing on continuous improvement and embracing a culture of efficiency, fabricators can adapt to market changes while maintaining high quality standards.

FAQS

What are some key trends in sheet metal fabrication for 2024?

In 2024, some key trends include the integration of robotics, cost management strategies, the impact of supply chain dynamics, the use of digital twin technology, and a shift towards lean manufacturing practices.

How do collaborative robots benefit metal fabrication workshops?

Collaborative robots, or cobots, enhance efficiency by working alongside human workers, reducing repetitive tasks, and increasing precision, which ultimately leads to higher productivity and lower operational costs.

What are some effective cost management strategies for fabricators?

Five key strategies include optimizing operational workflows, investing in automation, utilizing predictive maintenance, negotiating better supplier contracts, and incorporating lean practices to minimize waste.

How can manufacturers deal with material shortages?

Manufacturers can prepare for material shortages by diversifying their supply chains, building strong relationships with multiple suppliers, keeping an eye on market trends, and maintaining a buffer stock of critical materials.

Why is digital twin technology important for fabricators in 2024?

Digital twin technology allows fabricators to create virtual models of their processes, enabling simulation and analysis for optimization. This leads to improved efficiency, reduced errors, and better decision-making before actual production begins.